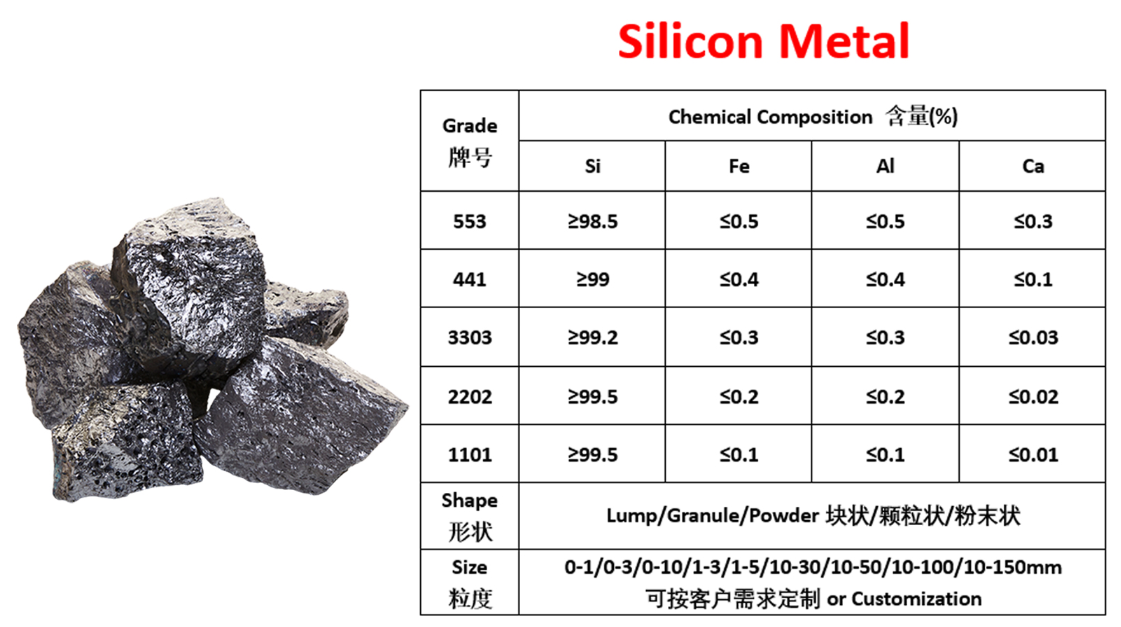

Silicon Metal

Introduction

Silicon metal is a product smelted from quartz and coke in an electric furnace. The main component silicon content is about 98% (in recent years, 99.99% of Si content is also available), and the remaining impurities are iron and aluminum, calcium, etc.

The classification of silicon metal is usually classified according to the content of three main impurities of iron, aluminum and calcium contained. According to the content of iron, aluminum and calcium in metal silicon, metal silicon can be divided into different grades

Production

Global industrial silicon production is concentrated in Asia, America and Europe. In 2020, the main sources of industrial silicon include China (76%), Brazil (7%), Norway (7%), the United States (4%), and France (3%).

Application

Casting: Silicon metal has a low melting point and is easy to melt, so it can be used to cast parts with light weight, high hardness and high temperature strength, such as automobile engines, aero engines, rocket engines, etc.

If you're interested in our products or have any questions,please don't hesitate to contact us!

JP

JP KR

KR CN

CN RU

RU