.jpg)

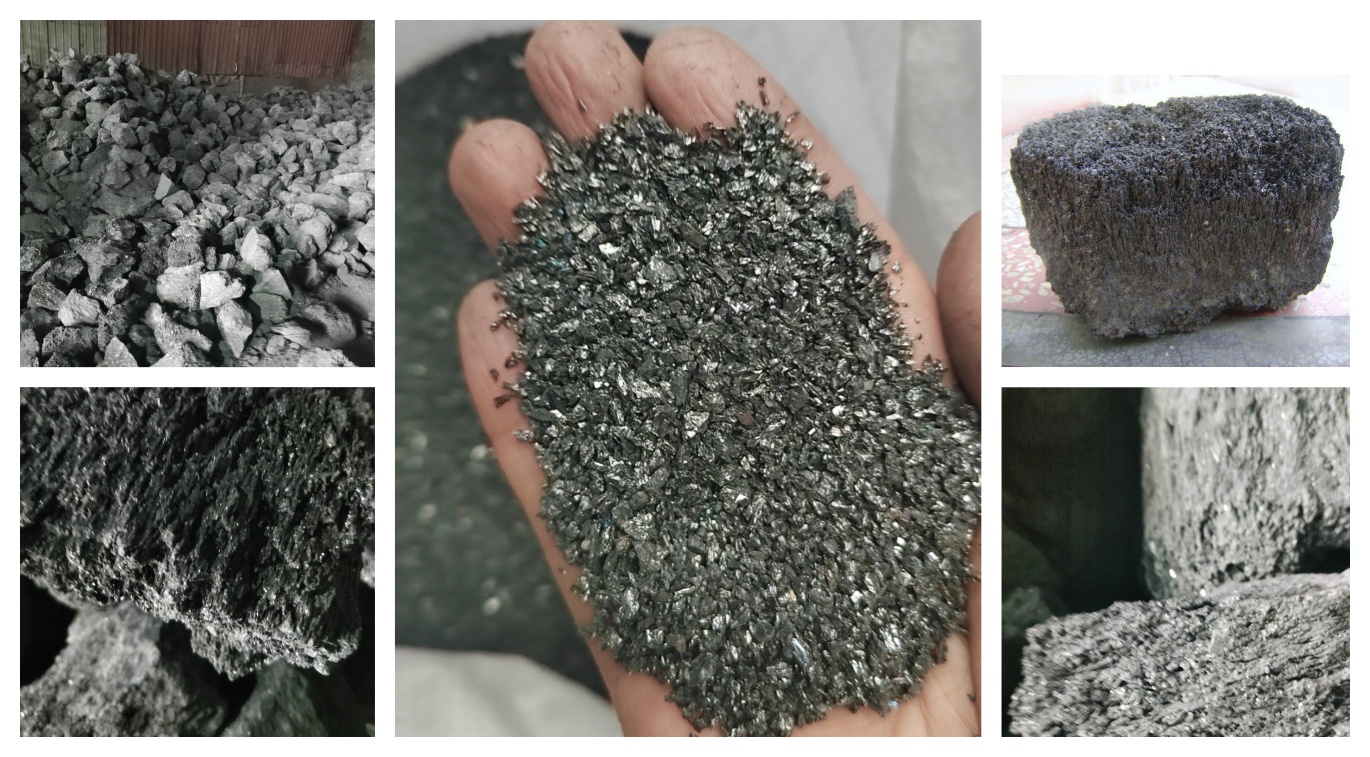

Silicon Carbide

- Specifications: SiC #60 #70 #80 #90 #98.5

- Shape: Grain/Powder

- Usage: Refractory Material/Steel Industry/Foundry Industry

- Particle size: 1-10mm,10-100mm or customized

| Specification | SiC | C F.C | Si+SIO2 | Fe2O3 | H2O |

| SiC95 | 95±3 | >0.3 | Trace | <1 | ≤0.8 |

| SiC85 | 85±3 | >0.6 | 10 | 2 | ≤0.8 |

| SiC80 | 80±3 | >1.0 | 25 | 3 | ≤0.8 |

| SiC75 | 75 | 10 | 18 | 3 | ≤0.8 |

| SiC65 | 65±3 | 20 | 20 | 4 | ≤0.8 |

Applications for black silicon carbide

1、Abrasives

It is mainly used for the grinding and polishing of grinding wheels, sandpaper, abrasive belts, whetstones, grinding blocks, grinding heads, grinding pastes, monocrystalline silicon, polycrystalline silicon in photovoltaic products, and piezoelectric crystals in the electronics industry.

2、steel

Taking advantage of silicon carbide's corrosion resistance, thermal shock resistance, wear resistance, and good heat conduction, it is used in the lining of large blast furnaces to improve the service life.

3、Metallurgical beneficiation

The hardness of silicon carbide is second only to diamond, and it has strong wear resistance. It is an ideal material for wear-resistant pipes, impellers, pump chambers, cyclones, and mine bucket linings. Its wear resistance is 5-20 times of cast iron and rubber service life,it is also one of the ideal materials for aviation runways.

If you're interested in our products or have any questions,please don't hesitate to contact us!

JP

JP KR

KR CN

CN RU

RU