The extraction methods of electrolytic manganese

Also known as metallic manganese, primarily include pyrometallurgical (thermal) and hydrometallurgical (electrolytic) processes. Pyrometallurgical production of metallic manganese typically results in purity levels not exceeding 95-98%, consumes high energy, and causes significant pollution. This method has gradually been phased out. On the other hand, hydrometallurgical electrolytic production of metallic manganese yields purity levels of 99.7-99.9% or higher and is associated with relatively lower pollution levels. It has become the primary method for metallic manganese production.

Electrolytic-produced metallic manganese has an appearance similar to iron, with irregular flake-like shapes. It has a hard and brittle texture, with one side being shiny and the other side rough. It can range in color from silver-white to brown, and it turns silver-gray when processed into powder. It is susceptible to oxidation in the presence of air, dissolves and releases hydrogen when it encounters dilute acids, and can decompose water to release hydrogen gas at slightly above room temperature. Due to its high purity and low impurity content, electrolytic-produced metallic manganese has found extensive applications in various fields, including steel production, non-ferrous metallurgy, electronics, chemical industries, environmental protection, food hygiene, welding electrode production, aerospace, and more.

China is a major participant in Electrolytic manganese production and consumption.

Continuous improvements in mining and processing technologies in China have made it possible to efficiently extract manganese from ores, increasing production and reducing environmental impact.

In particular, China TIANYUAN MANGANESE INDUSTRY GROUP Phase III 300,000-ton electrolytic metallic manganese project has significantly increased their production capacity, achieving a "three-fold jump" and filling a gap in the domestic and international market for electrolytic metallic manganese. The project, with an estimated total investment of 5.5 billion RMB and occupying 2,600 acres, employs energy-saving RPP electrolytic cells and automated processes including automatic analysis, automatic feeding, mechanical plate insertion, mechanical unloading, mechanical cleaning, and mechanical stripping.

The production process and equipment for electrolytic metallic manganese are computer-controlled. After reaching full production, the project is expected to contribute an annual industrial output value of 6 billion RMB and tax revenue of 1 billion RMB, providing employment for over 5,000 people.

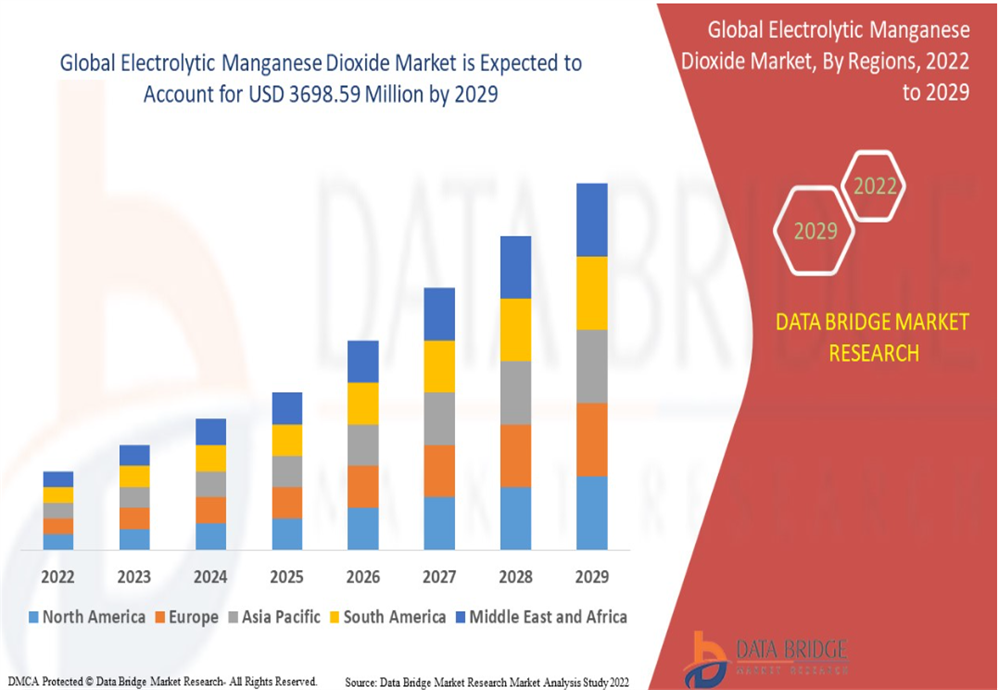

Globally, there is increasing attention to environmental concerns, emerging technologies, and environmental considerations, leading to a growing interest in manganese for various applications, including batteries and alloys. Environmental regulations and sustainability concerns have led to a focus on responsible mining practices and reducing emissions during the manganese mining and production process.

If you're interested in our products or have any questions,please don't hesitate to contact us!

JP

JP KR

KR CN

CN RU

RU